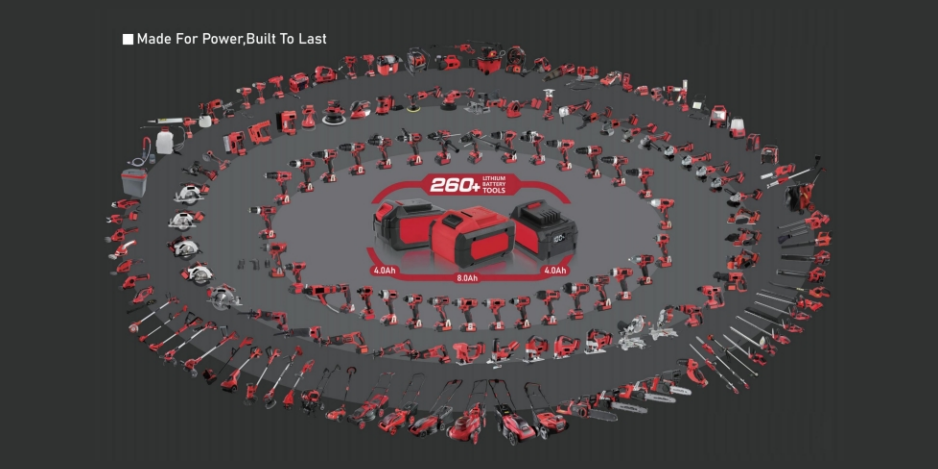

Hantechn@ Good Quality High Hardness Laser Welded Diamond Asphalt T.C.T Saw Cutting Blade

Elevate your cutting experience with the Hantechn@ High Hardness Laser Welded Diamond Asphalt T.C.T Saw Cutting Blade. Crafted with precision in mind, this blade is engineered to deliver superior performance in asphalt cutting. The combination of high hardness and laser-welded diamond technology ensures durability and precision in every cut, making it an indispensable tool for professionals and DIY enthusiasts alike.

|

Blade Thickness |

0.014in, 0.032in, 0.05in, 0.02in, 0.035in, 0.018in, 0.042in, 0.025in |

|

Blade Width |

1 1/2IN, 3/4IN, 1/2in, 1 1/4IN, 5/8in, 3/8in, 1/8IN, 1/4in, 1in, 3/16in, Other |

|

Arbor Size |

7/8IN, 10mm, 5/8in |

|

Teeth per Inch |

10, 24 |

|

Teeth |

140, 144 |

|

Blade Diameter |

18in, 12in |

|

Edge Height |

0.315in(8mm), 0.472in(12mm) |

|

Process Type |

HOT PRESS, High Frequency Welded, Laser welded, Cold PRESS |

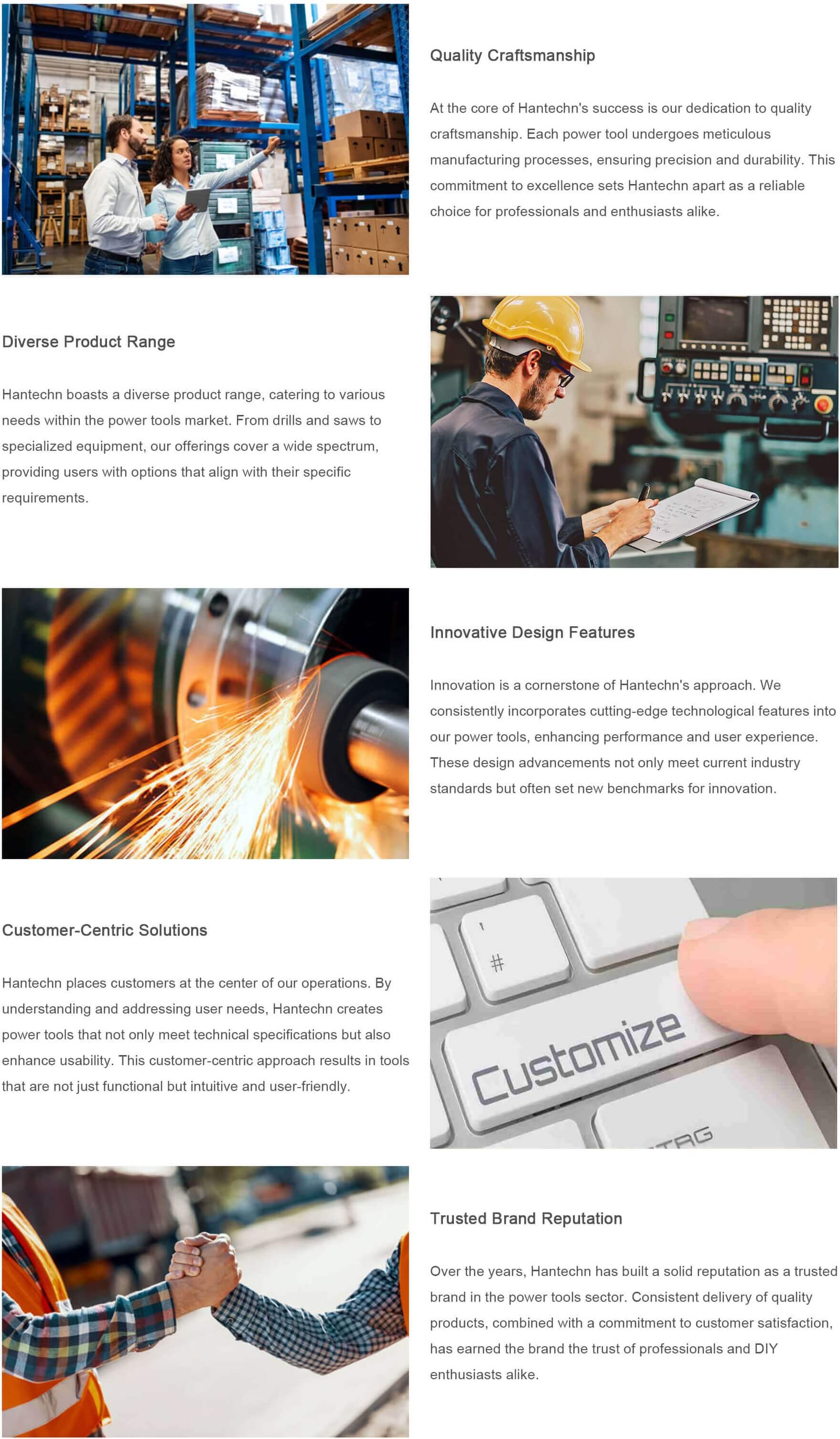

DIAMOND-HARD EDGE:

Laser-welded diamond technology delivers a razor-sharp cutting edge, ensuring precise and clean cuts for your asphalt cutting projects.

HIGH HARDNESS:

Experience the durability of a high-hardness blade, meticulously crafted to withstand the challenging conditions of asphalt cutting.

EFFICIENT ASPHALT CUTTING:

Swiftly and effortlessly cut through asphalt surfaces, saving valuable time and reducing effort on your asphalt cutting projects.

T.C.T SAW TECHNOLOGY:

Benefit from Tungsten Carbide Tipped (T.C.T) saw blade technology, offering extended blade life and optimal cutting performance for your asphalt cutting needs.

VERSATILE APPLICATION:

Ideal for both professionals and DIY enthusiasts, this blade is designed to tackle asphalt cutting projects with precision and efficiency.

DIAMOND-HARD PRECISION:

Laser-welded diamond technology ensures a cutting edge that is not only sharp but also precise, allowing you to achieve the high-quality cuts your projects demand.

HIGH HARDNESS DURABILITY:

Constructed with high hardness in mind, this blade is engineered for prolonged life and enduring cutting performance, making it a reliable choice for your asphalt cutting tasks.

SWIFT ASPHALT CUTTING:

Efficiently cut through asphalt surfaces with speed and ease, ensuring prompt project completion and professional results.

T.C.T SAW EDGE:

The Tungsten Carbide Tipped edge of the blade contributes to extended blade life and consistent cutting excellence, providing value for your investment.

PROFESSIONAL & DIY USE:

Whether you're a professional contractor or a DIY enthusiast, this versatile blade is suitable for a range of asphalt cutting applications.

CLEAN AND PRECISE CUTS:

Achieve clean and precise cuts, enhancing the overall quality and appearance of your asphalt cutting projects.

INDUSTRY-TRUSTED:

Count on Hantechn@ as your reliable partner for high-quality, precision cutting solutions. Join the ranks of those who trust our expertise for consistent and professional results in asphalt cutting.