A polisher, also known as a polishing machine or buffer, is a power tool used to enhance the appearance of surfaces by removing imperfections, scratches, or dullness and creating a smooth and glossy finish. It is commonly used in automotive detailing, woodworking, metalworking, and other industries where a high-quality finish is desired.

Composition of a Polisher

The composition of a polisher can vary depending on the specific product and its intended use. However, there are some common components and ingredients that are often found in polishers. Here are a few key components:

Abrasives:

Polishers often contain abrasive materials that help to remove imperfections and create a smooth surface. These abrasives can be in the form of particles or compounds, such as aluminum oxide, silicon carbide, or diamond dust. The type and size of the abrasive used can vary depending on the level of polishing required and the material being polished.

Binders:

Binders are substances that hold the abrasive particles together and help them adhere to the polishing pad or disc. Common binders include resins or polymers that provide cohesion and stability to the abrasive material.

Lubricants:

Lubricants are used in polishers to reduce friction and heat generated during the polishing process. They help to prevent the polishing pad or disc from overheating and minimize the risk of damage to the surface being polished. Lubricants can be in the form of oils, waxes, or water-based solutions.

Solvents:

Some polishers may contain solvents that help dissolve or disperse certain substances, such as oils, grease, or contaminants on the surface being polished. Solvents can aid in the cleaning and preparation of the surface before polishing.

Additives:

Polishers may also contain various additives to enhance their performance or provide specific properties. These additives can include surfactants to improve spreading and wetting, anti-static agents to reduce static electricity, or corrosion inhibitors to protect metal surfaces.

It’s important to note that the composition of polishers can vary significantly depending on the specific product and its intended use. Different types of polishers, such as those used for automotive detailing, woodworking, or metal polishing, may have specific formulations tailored to the requirements of those applications.

When using polishers, it’s essential to carefully read and follow the manufacturer’s instructions and safety guidelines to ensure proper usage and achieve the desired results.

The history of polishers

The history of polishers is a fascinating journey that spans various industries and reflects advancements in materials, technology, and craftsmanship. From humble beginnings to sophisticated tools, let’s delve into the timeline of how polishers have evolved over the years:

Early Beginnings:

Hand Rubbing:

- Before the invention of mechanical polishers, achieving a polished finish relied on manual effort. Craftsmen used materials like abrasive powders and cloths to hand rub surfaces, a labor-intensive process that required skill and patience.

20th Century:

Introduction of Electric Polishers:

- With the advent of electricity, the early 20th century witnessed the emergence of electric polishers. These devices featured rotating brushes or pads powered by electric motors, significantly reducing the manual effort required for polishing tasks.

Automotive Industry Adoption:

- Electric polishers found rapid acceptance in the automotive industry for detailing and paint correction. This era saw the birth of specialized automotive polishers designed to enhance the aesthetic appeal of car finishes.

Late 20th Century:

Advancements in Orbital Motion:

- The late 20th century brought innovations in orbital motion technology. Orbital polishers, characterized by their circular and oscillating movements, gained popularity due to their user-friendly design and effectiveness in preventing swirl marks.

Dual-Action (DA) Polishers:

- Dual-action polishers, combining orbital and rotary movements, emerged as a solution to address the risk of holograms or swirls caused by traditional rotary polishers. DA polishers became widely used for automotive detailing and other delicate polishing tasks.

21st Century:

Technological Integration:

- The 21st century witnessed the integration of advanced technologies into polishers. Variable speed settings, ergonomic designs, and digital controls became standard features, enhancing user control and efficiency.

Specialized Polishers:

- The demand for specialized polishers grew across industries. From metal polishing to woodworking and even electronic device polishing, manufacturers developed polishers tailored to specific materials and applications.

Cordless Polishers:

- Cordless polishers, powered by rechargeable batteries, gained popularity, offering increased mobility and convenience. This development revolutionized the user experience, especially in automotive detailing where maneuverability is crucial.

Present Day:

Continued Innovation:

- Continuous innovation in materials, motor technology, and polishing compounds ensures that modern polishers deliver superior results with precision and speed. The market offers a diverse range of polishers catering to professionals and hobbyists alike.

From the manual efforts of craftsmen to the sophisticated electric and cordless polishers of today, the evolution of polishers reflects a commitment to achieving impeccable finishes across various surfaces. Whether used in automotive detailing, woodworking, or industrial applications, polishers continue to play a vital role in enhancing the aesthetic appeal of diverse materials.

Types of Polishers

A. Orbital Polishers:

- Mechanism: These polishers move in an orbital motion, oscillating in a circular pattern. They are user-friendly, making them suitable for beginners and general polishing tasks.

- Applications: Ideal for light to moderate polishing, commonly used for car detailing and furniture projects.

B. Rotary Polishers:

- Mechanism: Rotary polishers have a direct and fixed rotation, providing powerful polishing capabilities. They are typically preferred by professionals due to their efficiency.

- Applications: Suitable for heavy-duty tasks, such as removing deep scratches from car paint or restoring heavily weathered surfaces.

C. Dual-Action (DA) Polishers:

- Mechanism: DA polishers combine both rotary and orbital movements, offering versatility and minimizing the risk of swirl marks or holograms.

- Applications: Commonly used for automotive detailing, these polishers provide effective results with reduced risk of paint damage.

How Polishers Work

Polishers are essential tools in achieving a flawless finish on various surfaces. Let’s delve into the intricacies of their operations, exploring three primary mechanisms: rotary motion, dual-action, and orbital movement.

A. Rotary Motion Explanation

Rotary polishers, also known as circular polishers, operate on a straightforward principle of spinning in a circular motion. The rotary motion is characterized by the pad’s constant circular movement, akin to a drill or a grinding tool. Key points to understand about rotary polishers include:

1. High-Speed Rotation:

- Rotary polishers are known for their high-speed rotation, making them effective in removing heavy defects like scratches and swirl marks.

- The spinning motion generates heat, requiring careful control to prevent damage to the paint or surface.

2. Professional-Grade Polishing:

Ideal for professionals or experienced users due to the potential risk of burning the paint if not handled with care.

Suited for tasks that demand aggressive paint correction.

B. Dual-Action Mechanism

Dual-action polishers, also referred to as random orbital polishers, combine both a spinning and oscillating motion. This dual-action mechanism provides a safer and more user-friendly approach to polishing. Key features of dual-action polishers include:

1. Simultaneous Spinning and Oscillation:

Dual-action polishers simulate hand polishing but with the efficiency of a machine.

The pad not only spins but also moves in an oscillating motion, reducing the risk of heat build-up and paint damage.

2. Safe for Beginners:

Dual-action polishers are beginner-friendly, making them an excellent choice for enthusiasts who are new to machine polishing.

They are less likely to cause paint burns or swirl marks, offering a forgiving polishing experience.

C. Orbital Movement Details

Orbital polishers, sometimes known as random orbit polishers, incorporate a distinct movement that sets them apart from other types. Understanding the orbital movement involves grasping the following concepts:

1. Circular and Eccentric Movement:

Orbital polishers combine a circular spinning motion with an eccentric orbit.

The eccentric orbit ensures that the pad moves in a more varied pattern, minimizing the risk of holograms or swirl marks.

2. Gentle yet Effective Polishing:

Orbital polishers strike a balance between the power of rotary polishers and the safety of dual-action polishers.

They are suitable for a range of tasks, offering effective paint correction with a lower risk of damage.

In conclusion, the effectiveness of polishers lies in their ability to cater to specific needs. Rotary polishers deliver professional-grade results but require expertise, while dual-action and orbital polishers provide safer options for both beginners and experienced users. Understanding these mechanisms empowers users to choose the right polisher for their specific polishing goals.

Common Uses of Polishers

Polishers are versatile tools that find application in various industries, enhancing the appearance and smoothness of different surfaces. Here are some common uses of polishers:

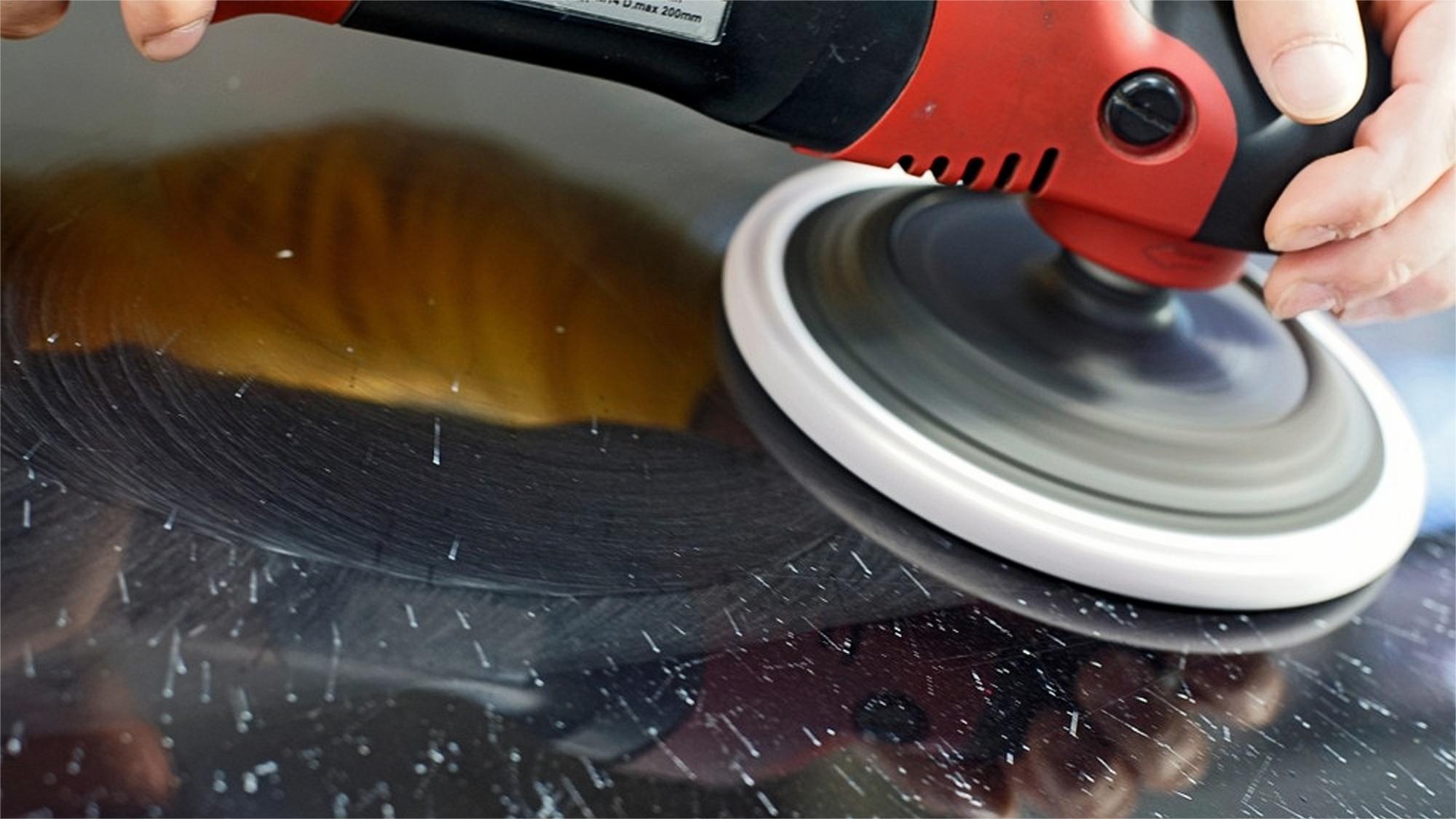

A. Automotive Detailing:

Polishers play a crucial role in automotive detailing, where achieving a flawless and glossy finish is paramount. They are used to remove scratches, swirl marks, and oxidation from car paint, restoring the vehicle’s shine and luster.

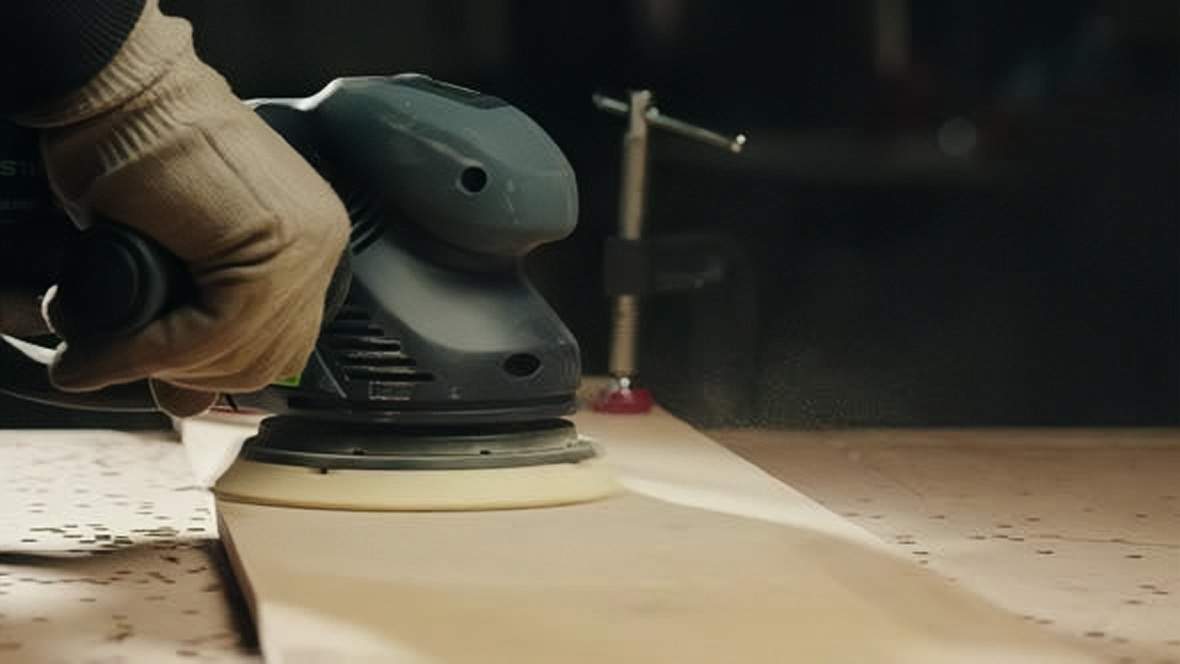

B. Woodworking:

In woodworking, polishers contribute to achieving smooth and polished finishes on wooden surfaces. Whether crafting furniture, cabinets, or intricate woodwork, polishers help bring out the natural beauty of the wood.

C. Metal Polishing:

Metal surfaces benefit from polishing to remove tarnish, scratches, or oxidation. Polishers are employed to restore the shine and smoothness of metals like chrome and stainless steel, enhancing their aesthetic appeal.

D. Marble and Stone Surfaces:

Polishers are extensively used in the care of marble and stone surfaces. Whether for countertops, floors, or decorative stone pieces, polishers bring out the natural luster of these materials, creating a polished and refined look.

E. DIY Projects:

Enthusiasts engaging in do-it-yourself (DIY) projects leverage polishers for various tasks. From restoring faded paint on household items to polishing metal fixtures, DIYers use polishers to enhance the visual appeal of their projects.

The versatility of polishers extends beyond these common uses, finding applications in diverse industries and projects. Whether you’re a professional craftsman, automotive enthusiast, or a homeowner with a passion for DIY, a quality polisher is an invaluable tool for achieving impeccable finishes and enhancing the overall aesthetic of surfaces.

Tips for Effective Polishing

Achieving a perfect polish involves more than just using the right tool. Here are essential tips to ensure your polishing efforts yield impeccable results:

A. Choose the Right Polish:

Selecting the appropriate polish for the material you’re working on is crucial. Different surfaces require specific formulations, so ensure you use a polish tailored to the task at hand. Whether it’s automotive paint, wood, or metal, the right polish enhances effectiveness and ensures a polished finish.

B. Start with a Clean Surface:

Before you begin polishing, make sure the surface is free from dirt, dust, or debris. Cleaning the area beforehand prevents scratches and ensures a smoother polishing process. Remove any contaminants to achieve the best possible finish.

C. Use Proper Technique:

Each type of polisher requires a specific technique for optimal results. Whether you’re using an orbital, rotary, or dual-action polisher, follow the recommended technique. Using the right motions and angles ensures efficient polishing without causing damage to the surface.

D. Apply Even Pressure:

Consistent pressure is key to achieving uniform results. Apply even pressure across the entire surface you’re polishing. This ensures that the polish is distributed evenly, preventing uneven polishing and potential damage to the material.

By following these tips, you’ll enhance the effectiveness of your polishing efforts, whether you’re working on your car, woodworking projects, or any other surface that requires a polished finish. Remember, the right polish, a clean surface, proper technique, and even pressure are the pillars of successful and flawless polishing.

Features to Consider When Choosing a Polisher

Selecting the right polisher is essential for achieving optimal results in your polishing projects. Here are key features to consider when making your decision:

A. Power and Speed Settings:

Look for a polisher with adjustable power and speed settings. Different materials and tasks may require varying levels of power. Having control over the speed allows for precision in polishing and prevents damage to sensitive surfaces.

B. Pad Size and Type:

Consider the size of the polishing pad and the type of pad it comes with. Larger pads cover more surface area, making them suitable for bigger projects, while smaller pads offer more precision. Different pad materials are designed for specific tasks, such as cutting, polishing, or finishing.

C. Variable Speed Control:

A polisher with variable speed control provides flexibility for different applications. Being able to adjust the speed allows you to tailor the polishing process to the specific requirements of the material you’re working on.

D. Ergonomic Design:

Choose a polisher with an ergonomic design for comfort during extended use. Look for features such as a comfortable grip, balanced weight distribution, and easy-to-reach controls. An ergonomic design reduces user fatigue and enhances overall control.

E. Corded vs. Cordless:

Consider whether you prefer a corded or cordless polisher. Corded models provide continuous power but may limit mobility. Cordless models offer greater flexibility but require battery management. Choose based on your specific needs and the convenience of mobility.

F. Build Quality and Durability:

Invest in a polisher with a robust build quality to ensure longevity and durability. High-quality materials and construction contribute to the tool’s overall performance and lifespan.

G. Ease of Pad Changing:

Look for a polisher with a quick and easy pad-changing mechanism. This feature streamlines the process of transitioning between different polishing tasks, saving time and effort during your projects.

H. Safety Features:

Prioritize polishers with safety features such as overload protection, which prevents overheating, and a secure on/off switch. Safety should always be a top consideration when working with power tools.

I. Brand Reputation and Reviews:

Research the reputation of the brand and read user reviews to gauge the reliability and performance of the polisher. A reputable brand with positive reviews is more likely to provide a quality product.

Considering these features will guide you in selecting the right polisher for your specific needs, whether you’re engaged in automotive detailing, woodworking, or any other polishing project.

Step-by-Step Guide to Polishing

Polishing is a transformative process that enhances the appearance of surfaces. Here’s a comprehensive step-by-step guide to achieving a flawless finish:

A. Preparation of the Surface

1. Clean the Surface Thoroughly:

- Begin by washing the surface to remove any dirt, grime, or contaminants.

- Use a gentle automotive or surface cleaner to ensure a clean starting point.

2. Inspect for Imperfections:

- Carefully examine the surface for scratches, swirl marks, or other imperfections.

- Identify areas that require specific attention during the polishing process.

3. Mask Off Sensitive Areas:

- Protect adjacent surfaces, trims, or areas prone to damage by masking them off with painter’s tape.

- Ensure a clear workspace to avoid accidental damage during the polishing process.

4. Clay Bar Treatment (Optional):

- Consider using a clay bar to remove embedded contaminants from the surface.

- Run the clay bar gently over the surface to achieve a smooth foundation for polishing.

B. Choosing the Right Polish

1. Identify the Paint Type:

- Determine whether the surface has single-stage or clear-coated paint.

- Different paints may require specific types of polish.

2. Select the Appropriate Abrasiveness:

- Choose a polish with the right level of abrasiveness based on the severity of imperfections.

- Less abrasive polishes are suitable for mild defects, while more abrasive ones address deeper scratches.

3. Consider Finishing Polishes:

- For surfaces with minor imperfections or those in good condition, opt for a finishing polish to enhance gloss and shine.

- Finishing polishes are less abrasive and contribute to a smooth, reflective surface.

4. Test in a Small Area:

- Prior to full-scale application, test the chosen polish in a small, inconspicuous area.

- This allows you to assess its effectiveness without committing to the entire surface.

C. Proper Technique for Polishing

1. Apply the Polish:

- Use a foam or microfiber applicator pad to apply a small amount of polish onto the surface.

- Start with a dime-sized amount and add more if needed.

2. Use the Right Polishing Tool:

- Choose the appropriate polishing tool – rotary, dual-action, or orbital – based on your skill level and the task at hand.

- Ensure the tool is in good condition, and the polishing pad is clean and suitable for the chosen polish.

3. Polishing Motion:

- Work in sections, applying the polish in overlapping, straight lines.

- Adjust the pressure and speed of the polishing tool based on the level of correction required.

4. Monitor Progress:

- Regularly inspect the polished area to gauge the progress.

- Wipe away excess polish with a clean microfiber towel to assess the true condition of the surface.

5. Repeat as Needed:

- If necessary, repeat the polishing process until the desired level of correction is achieved.

- Be mindful not to over-polish, especially on clear-coated surfaces.

6. Final Inspection:

- Once satisfied with the results, carefully inspect the entire polished surface.

- Remove any remaining polish residue with a clean, dry microfiber towel.

7. Apply a Sealant or Wax (Optional):

- Consider applying a protective sealant or wax to enhance and preserve the polished finish.

- Follow the product instructions for proper application.

By following this step-by-step guide, you can master the art of polishing, transforming surfaces and achieving a stunning, rejuvenated appearance.

Benefits of Using a Polisher

Polishers are indispensable tools in the world of surface care, offering a multitude of benefits that go beyond aesthetics. Here’s a breakdown of the key advantages of incorporating a polisher into your surface maintenance routine:

A. Achieving a Professional Finish

1. Flawless Surface Correction:

Polishers excel in correcting imperfections such as swirl marks, scratches, and oxidation, delivering a level of correction that is challenging to achieve by hand.

2. Enhanced Gloss and Shine:

The mechanical action of a polisher, coupled with the right polishing compounds, enhances the gloss and shine of surfaces, providing a professional-grade finish.

3. Consistent Results:

Polishers ensure uniform application and distribution of polishing compounds, resulting in consistent and reliable outcomes across the entire surface.

B. Time and Effort Savings

1. Efficiency in Correction:

Compared to manual methods, polishers significantly reduce the time and effort required for surface correction, making them ideal for larger projects.

2. User-Friendly Operation:

Modern polishers, especially dual-action and orbital models, are designed to be user-friendly, allowing both professionals and enthusiasts to achieve impressive results with ease.

3. Faster Surface Enhancement:

The rotary or oscillating motions of polishers enable faster and more efficient surface enhancement, saving valuable time in comparison to traditional hand polishing.

C. Long-Term Benefits for Surfaces

1. Surface Preservation:

Regular use of a polisher with appropriate polishes and sealants helps preserve the integrity of surfaces, preventing deterioration caused by environmental factors.

2. Protection Against Contaminants:

Polishers contribute to the removal of contaminants, such as oxidation and embedded dirt, protecting surfaces from potential long-term damage.

3. Extended Surface Lifespan:

By addressing imperfections and applying protective products, polishers contribute to extending the lifespan of surfaces, whether it’s automotive paint, furniture, or other materials.

4. Reduced Maintenance Frequency:

Surfaces that undergo polishing maintenance require less frequent touch-ups and detailing, reducing the overall maintenance workload over time.

Polishing in Different Industries

Polishing is a versatile technique that transcends industries, providing a transformative touch to diverse materials and surfaces. Let’s explore how this essential process is applied in different sectors:

A. Automotive Detailing

1. Surface Restoration:

In automotive detailing, polishers are used to restore and enhance the appearance of vehicle paint.

They effectively remove swirl marks, scratches, and oxidation, rejuvenating the paintwork.

2. Gloss Enhancement:

Polishers contribute to the gloss enhancement of automotive surfaces, delivering a showroom-like finish.

They are instrumental in achieving a professional, reflective shine on cars, motorcycles, and other vehicles.

3. Headlight Restoration:

Polishers play a crucial role in headlight restoration by removing haze and scratches, improving visibility and safety.

4. Metal and Chrome Finishing:

Beyond paint, polishers are utilized for metal and chrome finishing on various automotive components, ensuring a polished and corrosion-resistant surface.

B. Woodworking and Furniture

1. Wood Surface Smoothing:

In woodworking, polishers contribute to smoothing wooden surfaces, eliminating imperfections and enhancing the natural grain.

2. Stain and Finish Application:

Polishers aid in the application of wood stains and finishes, ensuring even distribution and a uniform appearance.

3. Furniture Restoration:

Antique furniture restoration often involves the use of polishers to revive and preserve the original beauty of the wood.

4. Varnish and Lacquer Polishing:

Polishers are employed to achieve a flawless finish when applying varnish or lacquer to furniture, creating a durable and aesthetically pleasing surface.

C. Metal and Jewelry Polishing

1. Metal Surface Finishing:

In the metalworking industry, polishers are used to finish and polish metal surfaces, providing a smooth and lustrous appearance.

2. Jewelry Polishing:

Jewelry makers utilize polishers to refine and enhance the shine of precious metals, gemstones, and intricate details.

3. Removing Oxidation:

Polishers play a vital role in removing oxidation and tarnish from metal surfaces, restoring their brilliance.

4. Precision Polishing for Components:

In precision engineering, polishers are employed to refine the surfaces of metal components, ensuring tight tolerances and a polished finish.

The art of polishing is a universal practice with applications spanning automotive detailing, woodworking and furniture, and metal and jewelry polishing. The transformative effects of polishers contribute not only to aesthetic improvements but also to the preservation and longevity of surfaces across various industries. Whether it’s bringing back the shine to a classic car, enhancing the beauty of wooden furniture, or refining the brilliance of jewelry, polishers play a pivotal role in achieving excellence across diverse sectors.

Polishing vs. Waxing

Polishing and waxing are fundamental steps in surface care, each serving distinct purposes in the pursuit of a flawless finish. Let’s delve into the differences, when to employ each technique, and how combining them can yield optimal results:

A. Clarifying the Differences

1. Polishing:

Objective:

The primary goal of polishing is to correct imperfections in the surface, such as scratches, swirl marks, and oxidation.

Process:

Polishing involves the use of abrasives to remove a thin layer of the surface material, leveling out irregularities and restoring a smooth, even finish.

Result:

The outcome of polishing is a refined, corrected surface that exhibits enhanced gloss and clarity.

2. Waxing:

Objective:

Waxing focuses on protecting the surface by creating a sacrificial layer that shields against environmental elements, UV rays, and contaminants.

Process:

Wax is applied over the polished surface, forming a protective barrier that adds depth, shine, and water-beading properties.

Result:

The result of waxing is a well-protected surface with added luster and a barrier against potential damage.

B. When to Polish and When to Wax

1. When to Polish:

Surface Imperfections:

Polish when the surface has imperfections like scratches, swirl marks, or oxidation that need correction.

Preparation for Protection:

Before waxing, as polishing prepares the surface for the application of protective products.

2. When to Wax:

After Polishing:

Once the surface has been polished and imperfections addressed, waxing follows to protect and enhance the polished finish.

Routine Maintenance:

Periodically wax surfaces to maintain protection and preserve the polished appearance.

Seasonal Application:

Apply wax seasonally to shield against specific weather conditions, such as UV rays, rain, or snow.

C. Combined Approach for Optimal Results

1. Sequential Application:

Polish First, Wax Second:

Following a sequential approach ensures that imperfections are addressed through polishing before applying the protective layer of wax.

Enhanced Depth and Shine:

The combined approach results in a surface that not only boasts corrected imperfections but also exhibits enhanced depth, shine, and protection.

2. Regular Maintenance:

Periodic Waxing:

Implement a routine of regular waxing to maintain the protective layer and prolong the polished finish.

Occasional Polishing:

As needed, polish the surface to address new imperfections or maintain the desired level of gloss.

3. Choosing the Right Products:

Compatible Formulas:

Ensure that the polishing and waxing products used are compatible to achieve optimal adhesion and results.

Quality Matters:

Select high-quality products for both polishing and waxing to maximize effectiveness and durability.

In conclusion, understanding the differences between polishing and waxing is essential for effective surface care. Knowing when to polish and when to wax, and adopting a combined approach, allows for a holistic strategy that addresses both correction and protection. The result is a surface that not only looks refined and glossy but also enjoys prolonged protection against the elements.

Maintaining Your Polisher

Proper maintenance of your polisher is key to ensuring consistent performance and extending its lifespan. Let’s explore essential tips for keeping your polisher in optimal condition:

A. Cleaning and Storage Tips

1. Post-Use Cleaning:

After each use, clean the polishing pad and any residue on the polisher’s surface.

Use a brush or compressed air to remove polish residues from intricate parts.

2. Pad Inspection:

Regularly inspect the condition of the polishing pads for wear and tear.

Clean or replace pads as needed to maintain effective polishing.

3. Exterior Wipe-Down:

Wipe down the exterior of the polisher with a damp, clean cloth to remove any accumulated dust or polish residue.

Pay attention to ventilation areas and cooling vents to ensure optimal airflow.

4. Storage in a Case or Bag:

Store the polisher in a dedicated case or bag to protect it from dust, moisture, and potential damage.

Ensure the storage area is cool and dry to prevent corrosion.

5. Cord Management:

Properly coil and secure the power cord to avoid kinks and potential damage.

Store the cord away from sharp objects or heavy items that could cause abrasion.

B. Regular Maintenance Checks

1. Inspect Power Cord:

Check the power cord for any signs of fraying, cuts, or exposed wires.

Replace damaged cords immediately to prevent electrical hazards.

2. Fastener Tightening:

Periodically check and tighten any fasteners, bolts, or screws on the polisher to maintain stability during operation.

3. Motor Brushes Replacement:

If your polisher has replaceable motor brushes, monitor their wear.

Replace brushes as recommended by the manufacturer to ensure optimal motor performance.

4. Gear Housing Inspection:

Inspect the gear housing for any signs of oil leakage or damage.

Address any issues promptly to prevent further damage to internal components.

C. Troubleshooting Common Issues

1. Overheating:

If the polisher overheats, allow it to cool down before resuming use.

Check for proper ventilation and ensure the air vents are not blocked during operation.

2. Loss of Power:

If the polisher experiences a sudden loss of power, check the power cord for damage.

Ensure a stable power source and rule out electrical issues.

3. Unusual Vibrations:

Excessive vibrations may indicate an issue with the pad or internal components.

Inspect the pad for balance and check for any visible damage.

4. Uneven Polishing:

Uneven polishing may result from worn-out or uneven pads.

Replace or rotate pads regularly to ensure consistent results.

5. Strange Noises:

Unusual noises may signal problems with internal components.

If persistent, consult the manufacturer’s guidelines or seek professional assistance.

By incorporating these cleaning, storage, maintenance, and troubleshooting practices, you can maximize the performance and longevity of your polisher. Regular attention to these details ensures that your polisher remains a reliable tool for achieving exceptional surface finishes.

User Reviews and Recommendations

User reviews and recommendations provide valuable insights into the world of polishing, offering guidance on products, techniques, and preferences. Let’s explore the diverse sources of information:

A. Feedback from Professionals

1. Professional Detailers’ Insights:

Seek feedback from professional detailers who regularly use polishers in their work.

Platforms like detailing forums, social media groups, or industry-specific websites often feature discussions where professionals share their experiences and recommendations.

2. Online Portfolios and Reviews:

Explore online portfolios or reviews of professional detailing services.

Professionals often showcase their work, highlighting the tools and techniques they use. These visual references can be informative.

3. Industry Events and Seminars:

Attend industry events, seminars, or workshops where professionals gather.

Engaging with professionals in person provides an opportunity to ask questions, gather recommendations, and witness techniques firsthand.

B. Popular Brands and Models

1. Brand Reputation:

Research the reputation of polishing machine brands in the market.

Brands with a longstanding reputation for quality and durability are often reliable choices.

2. Model-Specific Reviews:

Look for reviews specific to popular polishing machine models.

Review platforms, e-commerce websites, and industry publications often feature detailed assessments of the pros and cons of specific models.

3. Consumer Reports and Ratings:

Explore consumer reports and ratings for polishing machines.

Independent testing organizations or consumer review websites may provide unbiased assessments of various models based on user experiences.

C. Community Discussions on Polishing Techniques

1. Detailing Forums and Groups:

Join online detailing forums and social media groups dedicated to car care and surface maintenance.

Engage in discussions with enthusiasts and professionals to gather insights into preferred polishing techniques and product recommendations.

2. YouTube Tutorials and Reviews:

Explore YouTube tutorials and reviews from detailing enthusiasts.

Video content often provides visual demonstrations of polishing techniques and showcases the results achieved with specific machines and products.

3. Blogs and Articles:

Read blogs and articles by experienced detailers and surface care experts.

Industry experts often share their knowledge, including preferred polishing techniques and recommendations for machines and products.

Leveraging user reviews and recommendations is a powerful way to navigate the world of polishing. Whether seeking insights from professionals, exploring popular brands and models, or engaging in community discussions on polishing techniques, the wealth of information available from those who have hands-on experience can guide you towards informed decisions. As you embark on your polishing journey, consider a diverse range of sources to gather well-rounded perspectives and make choices aligned with your specific needs and preferences.

Conclusion

In conclusion, our exploration of polishing has unraveled the transformative power of polishers across various industries. Let’s recap the key points, encourage readers to delve into the world of polishing, and reflect on the significance of these versatile tools.

A. Recap of Key Points

1. Polishing vs. Waxing:

We dissected the distinctions between polishing and waxing, understanding their unique roles in achieving a flawless finish.

2. Maintaining Your Polisher:

Explored essential tips for keeping your polisher in optimal condition, from cleaning and storage to regular maintenance checks and troubleshooting.

3. Polishing in Different Industries:

Examined how polishers play a pivotal role in automotive detailing, woodworking, furniture, metalwork, and jewelry polishing.

4. Benefits of Using a Polisher:

Unveiled the advantages of achieving a professional finish, saving time and effort, and securing long-term benefits for surfaces.

5. User Reviews and Recommendations:

Explored the wealth of insights from professionals, popular brands and models, and community discussions on polishing techniques.

B. Encouragement for Readers to Explore Polishing

Embarking on a polishing journey is an invitation to elevate the appearance and longevity of surfaces. Whether you’re a professional detailer, a woodworking enthusiast, or someone passionate about maintaining the brilliance of jewelry, exploring the world of polishers opens doors to endless possibilities. Take the initiative to experiment, learn, and refine your skills, discovering the joy of transforming surfaces with precision.

C. Final Thoughts on the Significance of Polishers

In the grand tapestry of surface care, polishers emerge as indispensable tools, weaving together correction, protection, and enhancement. Their significance lies not only in the immediate aesthetic improvements but also in the preservation of surfaces over time. Polishers empower individuals to craft surfaces that reflect excellence and attention to detail, contributing to a world where brilliance meets precision.

As you venture into the realm of polishing, remember that each pass of the polisher is a stroke of craftsmanship, shaping surfaces with the finesse of an artist. Embrace the journey, harness the power of polishers, and revel in the satisfaction of witnessing surfaces transform under your skilled hands.

Post time: Nov-16-2023